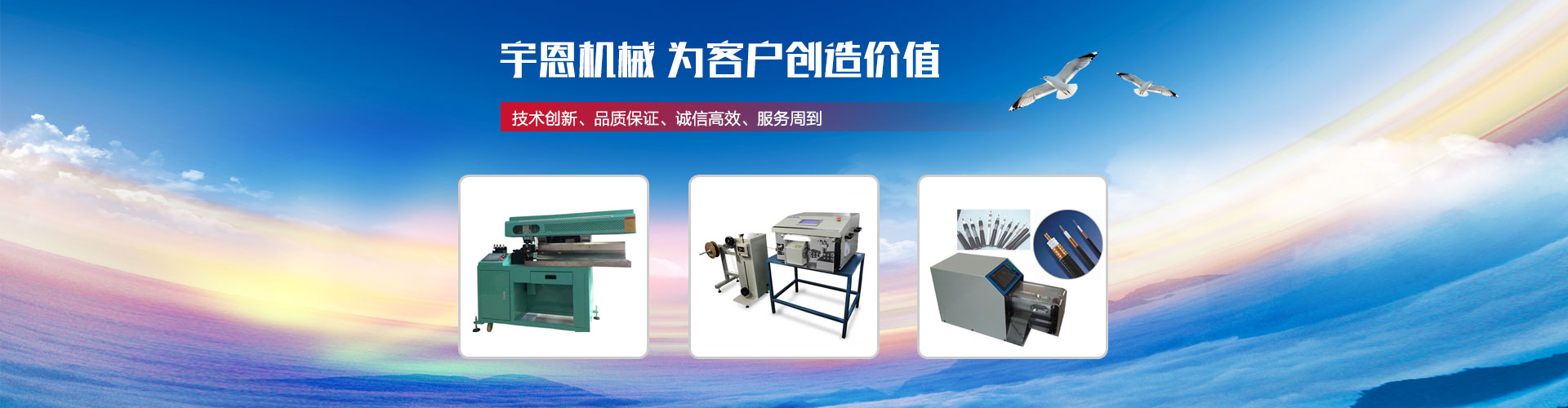

1. The five-function line computer stripping machine is an automatic line cutting machine which can cut off the dimensions of the wire material factory at high speed, peel the two ends, peel the one end and peel the other half.

2. Use servo motor to control the cutting line, peeling and other actions to make the cutting length more accurate.

3. The length change and the whole peel and half peel are set by pressing buttons, which is simple and fast.

4. It is easy and fast to change the peeling filling and cutting depth by means of fine-tuning rotation.

5. The speed can be divided into five sections, which can be set according to the wire specifications, so that both thick and thin lines can be produced stably.

6, the detection standard with low pressure, cylinder stuck motor abnormalities, consistent display count, and other functions, can automatically stop when the exception, and shows the detection problem in the man-machine interface, convenient and fast.

7. Quick troubleshooting to reduce downtime.

8. The best features are less adjustment technology, less pressure line, short adjustment time and convenient operation.

9. It can be matched with the line divider to complete the line dividing, line cutting and peeling actions to improve the production efficiency.

10. The machine can be pulled 50 times per minute for 600mm long line, more than 4 times as much as the tabletop 2-out wire stripping machine.